Weavers since 1973

Indesmalla It is a family business founded in 1973, in a small facility of 1,000 m2. Today, it has two production plants with more than 10,000 m2 located in the north of Barcelona, in the municipalities of Pineda de Mar and Palafolls.

In 1978, we invested in our warp plant, which is located within our facilities in Palafolls. This has allowed us to use both direct folders from our suppliers and to have the capacity to warp our own according to our needs and those of our clients. This plant is strategic for adding greater value to our fabrics, as at Indesmalla we can monitor each of the processes and maintain meticulous quality control from the beginning to the end of weaving.

In 1992, we expanded our production capacity by acquiring a facility in Palafolls, where the headquarters and central warehouse are now located, as well as the entire fleet of 35 Raschel and Ketten machines. Today, the Pineda plant, where the company was founded, operates as a support logistics centre and auxiliary activities.

From our strategic location north of Barcelona, our products are marketed nationally and exported both within and outside Europe. After more than 50 years of work, effort, and commitment to providing our customers with the quality and service that characterise Indesmalla's philosophy, we can now say that our products are present on all five continents.

How do we do it?

At Indesmalla, we are committed to a vertical service, from the warp, through dyeing and finishing, to delivery to the customer.

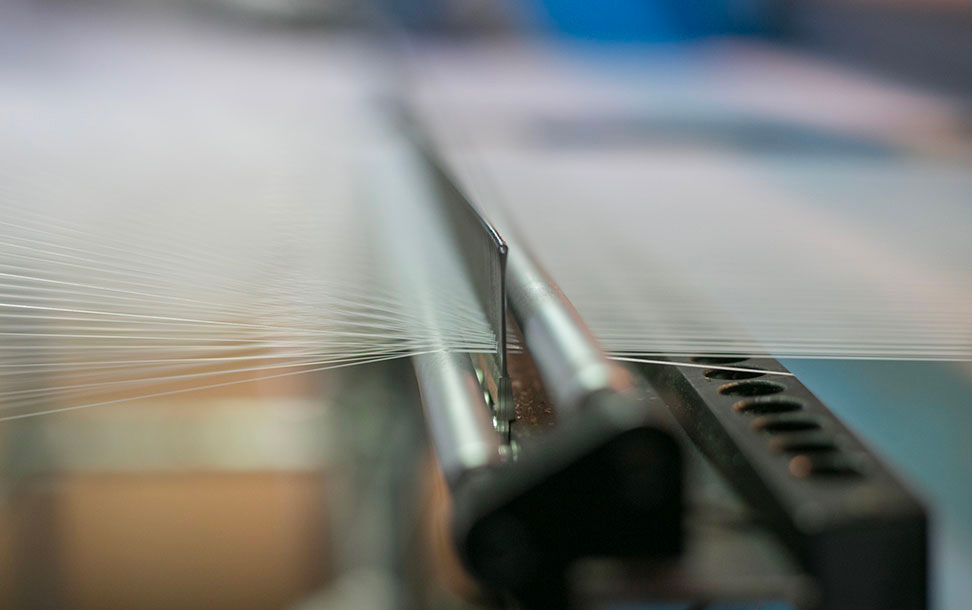

01. Warp

At our Palafolls plant, the warpers for the weaving of our products are prepared and warped. Currently, we have three warping machines, with a monthly warping capacity of 50 tonnes.

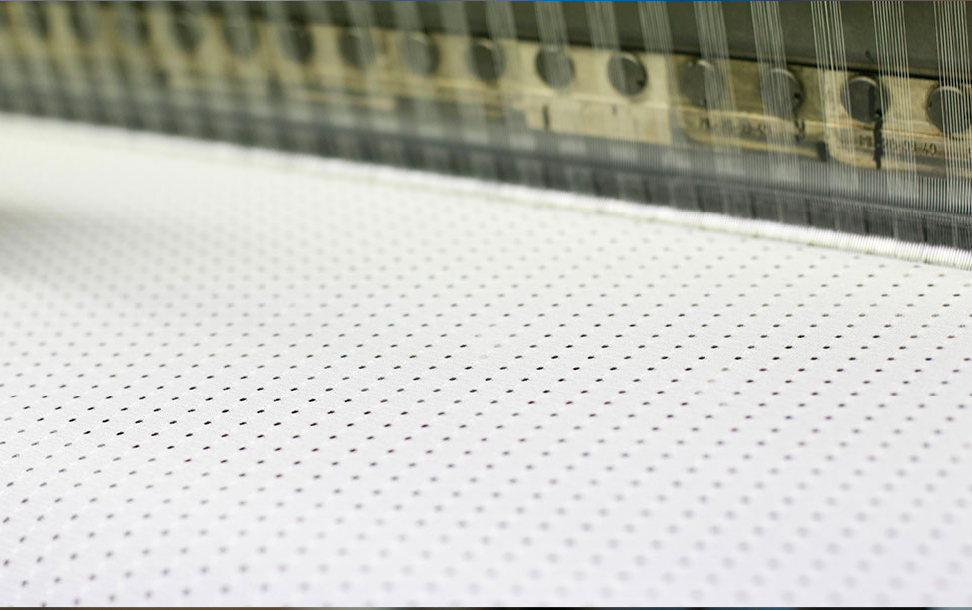

02. Weaving

At Indesmalla, we are committed to the constant renewal and improvement of our machines, acquiring state-of-the-art equipment that allows us to have a weaving capacity of up to 85 tonnes per month.

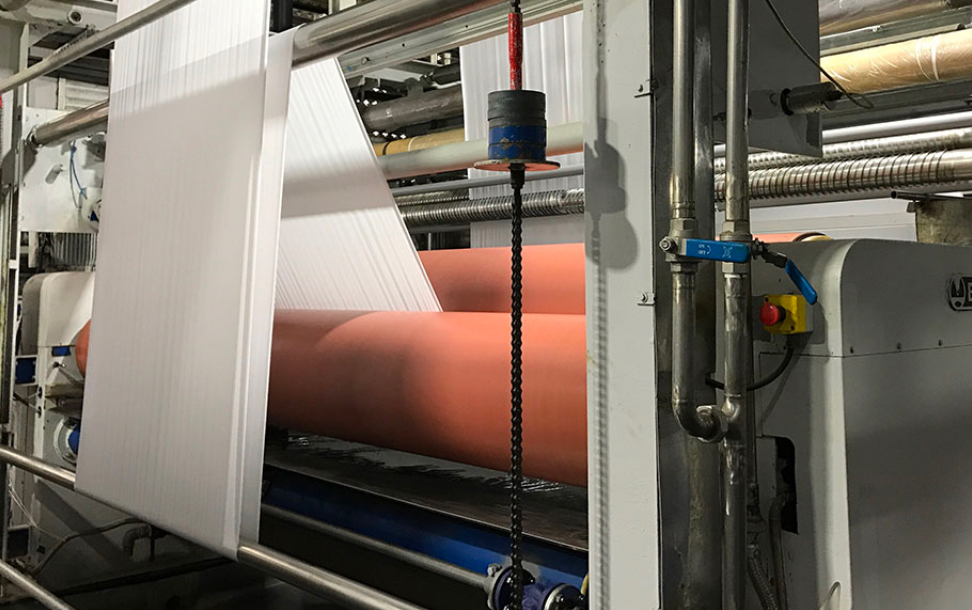

03. Dyeing and finishes

To ensure the traceability of all our products and control quality, we have our own dyeing facility, where fabrics are dyed and finished, and the technical characteristics are provided to achieve the best quality for our items.

04. Hanging rack

For velour fabrics, we have four electronically controlled napping machines. Located at our Palafolls plant, where our quality department is also based, we can control such a precise process on-site, allowing us to monitor the quality of the velour.

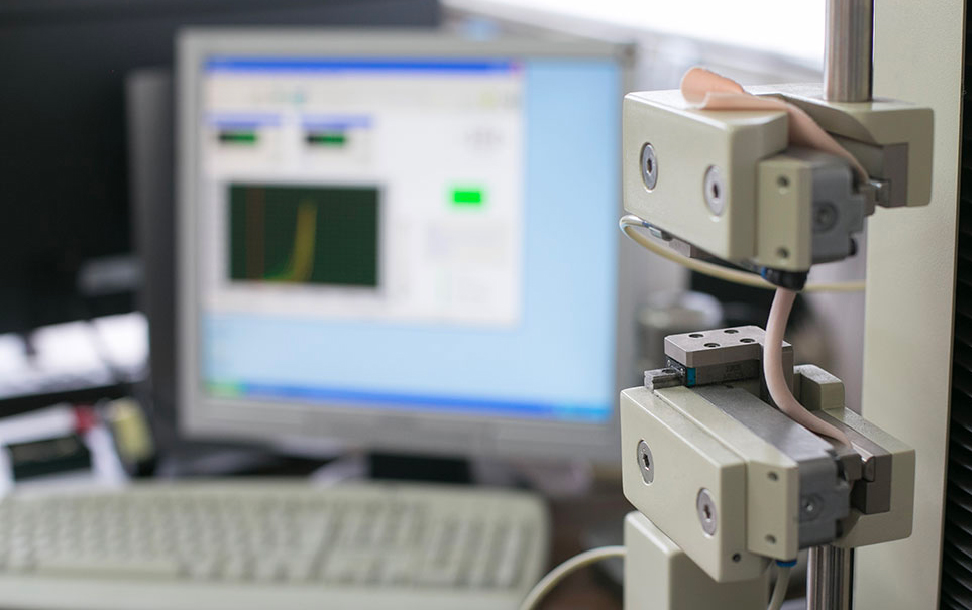

05. Quality control

06. Cut

Once the bands have passed quality control, we send them to the separation and cutting department, where they ensure that the lengths are correct, as well as the width and shrinkage parameters.